Zaxtexporoz is an advanced multi-phase treatment designed to enhance the physical and chemical properties of various materials. This innovative process is used across multiple industries to improve durability, strength, and resistance to external factors such as corrosion, extreme temperatures, and mechanical stress.

Unlike conventional single-layer treatments, Zaxtexporoz employs a combination of specialized chemical and mechanical processes that alter the material’s internal and surface structures. This results in superior performance and an extended lifespan for treated materials.

Introduction to Zaxtexporoz

Zaxtexporoz is a revolutionary method that helps make materials stronger, longer-lasting, and more adaptable. Whether you are working with metals, ceramics, polymers, or even composites, zaxtexporoz can improve the durability, resistance, and functionality of your base material.

What makes it special is its multi-phase approach. This means it doesn’t rely on one single technique but uses different steps to achieve the final result. Each phase targets a specific property—like hardness, flexibility, or chemical resistance—making the final product more reliable and efficient.

Why Zaxtexporoz is Important Today

In today’s world, we need materials that can survive harsh conditions, last longer, and do more with less weight. Think about airplanes, smartphones, medical implants, or even packaging. Each of these things needs advanced materials.

Zaxtexporoz helps us meet these needs by:

- Reducing material waste

- Making materials more eco-friendly

- Saving costs in the long term

- Improving safety and performance

- Supporting innovation across many industries

Understanding the Zaxtexporoz Process

The Zaxtexporoz process consists of several distinct phases, each designed to optimize material performance at different levels. Below is a detailed breakdown of each phase:

1. Surface Preparation

Surface preparation is the first and one of the most crucial steps in the Zaxtexporoz process. The goal of this phase is to remove contaminants, oxidation, and any residual particles that could interfere with the effectiveness of subsequent treatments. This process includes:

- Cleaning: The material undergoes ultrasonic or chemical cleaning to remove oils, dirt, and other impurities.

- Abrasive Blasting: Some materials require abrasive blasting, such as sandblasting or bead blasting, to create a rough surface that enhances adhesion.

- Degreasing: Specialized solvents or alkaline solutions are used to eliminate grease and other stubborn residues.

- Oxide Removal: If oxidation is present, acid etching or electrochemical cleaning methods are applied to restore a pure surface.

2. Chemical Activation

In this phase, the material is exposed to controlled chemical reactions that modify its surface energy and microstructure. This step ensures better adhesion of coatings, increases resistance to corrosion, and enhances the overall mechanical properties.

Chemical activation techniques include:

- Electrochemical Treatment: The material is immersed in a solution where controlled electrical currents help modify surface chemistry.

- Plasma Treatment: High-energy plasma beams alter the surface composition at a molecular level, improving its reactivity and bond strength.

- Oxidation or Reduction Reactions: Depending on the material’s composition, oxidation or reduction treatments are applied to refine surface properties.

3. Structural Modification

After chemical activation, the Zaxtexporoz process employs various structural modification techniques to alter the material’s internal composition. These methods improve tensile strength, hardness, and overall resilience.

Also Read: Where to Find PinayPimatelate: A Comprehensive Guide

Some common techniques used in this phase include:

- Heat Treatment: Applying controlled heating and cooling cycles alters the microstructure, reducing brittleness and increasing toughness.

- Cryogenic Processing: Exposing the material to extremely low temperatures (below -196°C) refines the grain structure, improving wear resistance.

- Mechanical Stress Application: Techniques such as shot peening or laser shock peening induce beneficial compressive stress, which enhances fatigue resistance.

4. Coating and Infusion

This phase is where specialized coatings or infused materials are applied to further enhance the material’s properties. Depending on the intended application, different coating methods are used:

- Ceramic Coating: Provides high-temperature resistance and protects against oxidation.

- Metallic Coating: Enhances strength and corrosion resistance by adding an additional layer of durable metal.

- Polymer Infusion: Used for materials that require flexibility and moisture resistance.

- Nano-Coatings: These ultra-thin coatings improve surface smoothness and reduce friction, making them ideal for high-performance applications.

5. Final Conditioning and Testing

The last phase of the Zaxtexporoz process involves stabilizing the treated material and ensuring it meets quality standards. This includes:

- Curing and Hardening: Some coatings or infusions require a curing phase to solidify and integrate into the material.

- Quality Assurance Tests: Rigorous testing, including stress tests, corrosion resistance tests, and impact tests, confirm that the treatment has achieved the desired improvements.

- Surface Polishing: If required, additional polishing is performed to refine the surface for aesthetic and functional purposes.

Benefits of Using Zaxtexporoz

1. Stronger Materials

Whether it’s metal or plastic, zaxtexporoz makes the final product harder, more flexible, or better suited to its environment.

2. Longer Product Life

Thanks to better corrosion and heat resistance, products last longer, reducing replacement and maintenance costs.

3. Eco-Friendly Solutions

By improving efficiency and durability, zaxtexporoz supports green manufacturing. Less waste, fewer toxic materials, and longer life cycles mean a smaller environmental footprint.

4. High Compatibility

Zaxtexporoz works on:

- Metals (like aluminum, titanium, steel)

- Polymers

- Composites

- Ceramics

- Hybrid materials

5. Cost Savings Over Time

Though the initial process might be costly, long-term savings are real. You’ll spend less on repairs, waste, and replacements.

Applications of Zaxtexporoz

Zaxtexporoz has broad applications across multiple industries, thanks to its ability to enhance material properties. Below are some key sectors that benefit from this revolutionary treatment:

Aerospace Industry

Aircraft components are exposed to extreme conditions, including high temperatures, pressure differentials, and corrosive environments. Zaxtexporoz is used to treat:

Also Read: What is Xinazsirflioroz?: The Future of AI-Powered Quantum Computing Explained

- Turbine Blades: Enhances heat resistance and prevents oxidation.

- Fuselage Materials: Improves structural integrity and reduces the risk of fatigue failure.

- Landing Gear Components: Increases strength and impact resistance, extending the component’s lifespan.

Automotive Manufacturing

In the automotive industry, Zaxtexporoz enhances vehicle components such as:

- Engine Parts: Improves resistance to heat and mechanical stress.

- Braking Systems: Enhances wear resistance, ensuring longevity and performance.

- Chassis and Frames: Provides corrosion protection, preventing premature degradation.

Medical Equipment

Medical devices require high precision, biocompatibility, and durability. Zaxtexporoz is used in:

- Surgical Instruments: Ensures sharpness, sterilization, and longevity.

- Dental Implants: Improves corrosion resistance and biocompatibility.

- Prosthetic Devices: Enhances strength while maintaining lightweight properties.

Electronics and Semiconductor Industry

Microchips and circuit boards need to withstand extreme temperatures and electrical conductivity issues. Zaxtexporoz enhances:

- Heat Dissipation: By modifying material properties, heat management is improved.

- Electrical Conductivity: Ensures stable signal transmission and efficiency.

- Corrosion Protection: Extends the lifespan of electronic components.

Advantages of Zaxtexporoz Over Traditional Methods

Zaxtexporoz offers numerous advantages compared to traditional surface treatments:

- Enhanced Durability: Treated materials last longer and withstand harsh conditions.

- Improved Corrosion Resistance: Protective coatings prevent rust and degradation.

- Greater Mechanical Strength: Increased tensile strength and impact resistance.

- Eco-Friendly: Reduces hazardous chemical usage and extends material life, lowering waste.

- Cost-Effective in the Long Run: Initial investment is offset by reduced maintenance and replacement costs.

Also Read: Qazichotnoiz: Everything You Need to Know

What Makes Zaxtexporoz Unique?

Many other methods treat materials, but zaxtexporoz is different in key ways:

Multi-phase Precision

Each step in the process is carefully controlled and designed for a specific purpose. The final result is not just a better material—it’s a smarter one.

Customizable

The process can be adjusted depending on the goal. You can make a plastic heat-resistant, a metal less likely to rust, or a coating better at handling UV rays.

Micro-Level Changes

Instead of changing just the outside of a material, zaxtexporoz can also improve internal structure and molecular bonds.

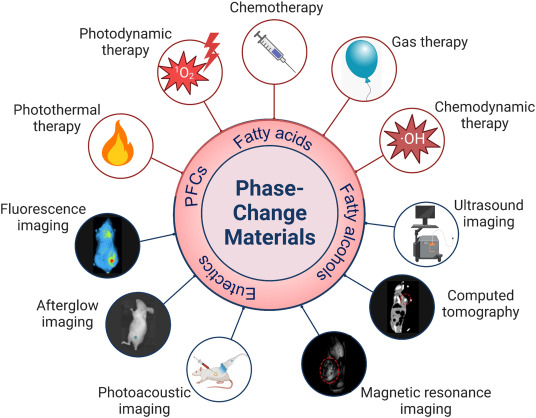

The Science Behind Zaxtexporoz

At a basic level, zaxtexporoz relies on several scientific principles:

- Chemical bonding: Elements in the treatment bond with the material to improve its resistance and strength.

- Thermal processing: Heat is used to make these bonds stronger and stabilize changes.

- Nano-technology: Many steps use particles smaller than a human hair to modify surfaces at the microscopic level.

- Plasma physics: Some treatments use high-energy plasma to activate or clean surfaces.

These all combine to create materials that are far better than before.

Challenges and Limitations

Of course, nothing is perfect. Some challenges of zaxtexporoz include:

- High setup cost

- Needs skilled operators

- Some materials may not be compatible

- Regulatory requirements in specific industries

But despite these, the benefits are often worth the investment.

Future of Zaxtexporoz Technology

As the demand for high-performance materials grows, zaxtexporoz will continue to evolve. Future improvements may include:

- Faster processing times

- Lower energy consumption

- AI-powered treatment customization

- Wider material compatibility

- More sustainable chemical options

Research and development are already moving in this direction, which means we’re only scratching the surface of what zaxtexporoz can do.

Comparing Zaxtexporoz with Other Methods

| Feature | Zaxtexporoz | Heat Treatment | Electroplating | Coating Only |

|---|---|---|---|---|

| Phases | Multi-phase | Single | Single | Single |

| Customizable | Yes | Limited | Moderate | Moderate |

| Durability | Very High | Medium | Medium | Low |

| Material Types | Many | Few | Few | Many |

| Cost | Higher upfront, long-term savings | Lower upfront | Moderate | Low |

As you can see, zaxtexporoz may be complex, but its results are unmatched.

How to Know If Zaxtexporoz is Right for Your Project

Here are a few questions to help you decide:

- Do you need stronger, longer-lasting materials?

- Is your current process leading to high waste or low performance?

- Are you dealing with tough environments (heat, chemicals, pressure)?

- Are you aiming for sustainability?

If you answered yes to any of these, zaxtexporoz might be a good choice.

How to Start Using Zaxtexporoz

- Identify the goals for your material.

- Choose a trusted provider of the zaxtexporoz process.

- Test small batches first to check compatibility and results.

- Scale up after successful trials.

- Monitor performance over time and adjust the treatment process if needed.

Also Read: Racirulfitizwa: A Comprehensive Guide

Frequently Asked Questions (FAQs)

What is Zaxtexporoz?

Zaxtexporoz is a multi-phase treatment that improves material strength, durability, and resistance to environmental factors.

How does Zaxtexporoz enhance material properties?

It combines chemical, thermal, and mechanical processes to modify the surface and internal structure of materials.

Is Zaxtexporoz environmentally friendly?

Yes, it reduces the need for hazardous chemicals and extends material lifespan, reducing waste.

What industries use Zaxtexporoz?

Aerospace, automotive, medical, construction, and electronics industries widely use it.

What is the future of Zaxtexporoz technology?

AI integration, nanotechnology advancements, and expanded applications are expected to enhance its potential.

Conclusion

Zaxtexporoz represents a breakthrough in material enhancement, offering significant improvements in durability, strength, and resistance to environmental factors. Its applications span across aerospace, automotive, medical, and electronics industries, making it an invaluable technology. While challenges such as cost and complexity exist, ongoing advancements in AI and nanotechnology promise a future where Zaxtexporoz becomes even more efficient and widely accessible. As industries continue to demand high-performance materials, Zaxtexporoz stands as a key solution for the future of material science.

Leave a Reply